- Greg Zekoff

If you’re new to environmental services and you need to gather data on your site’s subsurface conditions, selecting a deep groundwater sampling method for your project can be overwhelming. To choose the best technique and achieve the results you need, you must consider a variety of factors. Overall depth, geology, budget, suspected contaminant, borehole size, quantity of sample required, and drilling method should play a role in technology selection.

There are three things to know before you begin your groundwater sampling project. The type of aquifer, characteristics of the geologic formation, and the contaminants of concern you expect to find.

In my on-demand webinar Sampling 101: Methods of Collecting Environmental Samples During Drilling, I discuss different environmental sampling methods and the suitable lithologies for each, and I share real-life examples of how they’ve worked in the field.

In this blog post, we'll look at four deep groundwater sampling methods that are regularly used with casing advanced drilling systems (like hollow stem auger, sonic, and air rotary casing hammer). Note that direct push technology is another great way to collect environmental samples in shallow applications, but we’ll focus on the deeper applications here.

Temporary Well Installation

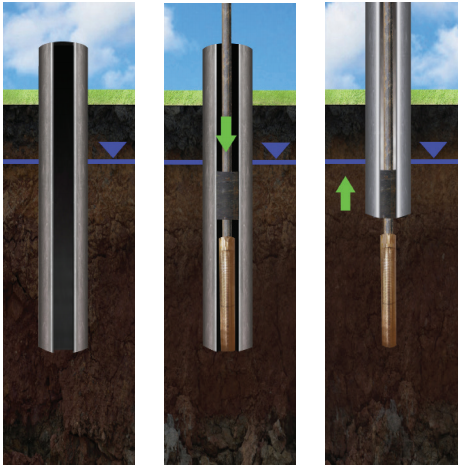

Temporary well installation is the simplest of groundwater sampling methods. It’s conducted by using a cased hole to run a small diameter casing with a short, perforated section at the bottom. Add a filter sand, pull back the outer casing, and voila! There is now a well to sample.

The drawbacks of temporary well installation are usually related to the cost; the process tends to be more time-consuming and thus more expensive compared to the other three methods discussed here. There is also a cost for the temporary well materials and, if contamination is present, for development/purge water disposal.

Isoflow® Discrete Groundwater Sampler

The ISOFLOW tool is another option for obtaining a high quality, discrete groundwater sample during drilling. This device typically consists of a small section of stainless steel screen that sits below a packer assembly. When the outer casing is pulled back to expose the screen, the packer assembly is lowered into the drill casing to the bottom of the hole. The packer stays in the casing to seal the tool and make sure that only the groundwater can flow through the screen. Once in place, this zone can be developed with pump or bailer and then purged to collect a high quality sample. It can also be used in some applications to provide low flow pump testing information.

ISOFLOW is a great option on sites where a high quality sample is needed, a large volume of sample is required, and where some well pumping information is advantageous. Samples collected by this method are typically less expensive than those collected via temporary well. Drawbacks include purge water disposal and some potential turbidity in the sample.

Additionally, this method can also be used as means of gauging or measuring the yield of an aquifer for the design of larger recovery or production wells. The way this works is that a pump test can be conducted using these same tools to help guide the engineer when exploring a site for a higher yield aquifer zone. This way there’s no need to committing to the construction of the final larger well(s) until this critical information is obtained.

The ISOFLOW tool consists of a small section of stainless steel screen that sits below a packer assembly. The outer casing is pulled back to expose the screen, the packer assembly is lowered into the drill casing to the bottom of the hole. The packer stays in the casing to seal the tool and make sure that only the groundwater can flow through the screen.

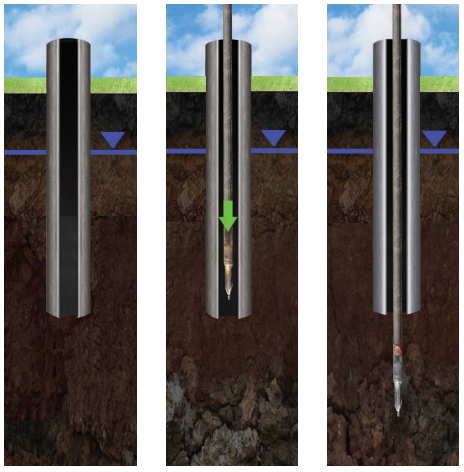

Push Ahead Groundwater Sampler

There are a variety of push ahead groundwater samplers on the market, and each has a different twist on the device operation. A push ahead sampler is sometimes referred to as a “Hydropunch,” which was the name of one of the first tools of this type (it is no longer available). These tools are called “push ahead” based on how they work: the tool is driven ahead of the drilling operation, where drilling disturbance has not occurred yet. The drill casing is not moved back for this device; instead, after being driven a distance of 18 to 24 inches, the device is pulled back and/or twisted a short distance to expose a screen. From there, a bailer can be run in the string to collect a water sample. A push ahead sampler often saves time compared to other methods because you don’t have to sample continuously to the terminal depth. Another reason many people use the push ahead method is that it minimizes the potential for cross contamination when collecting discrete samples, although turbidity – particulate matter in the samples – may be present.

The push ahead sampler tool is driven ahead of the drilling operation, where drilling disturbance has not occurred yet, minimizing the potential for cross contamination when collecting discrete groundwater samples.

Push ahead groundwater sampling is simple, efficient and cost-effective. This approach is effective when keeping the cost of collecting discrete groundwater samples low is a priority and when turbidity of the samples is not a concern.

When considering this methodology there needs to be a more complete understanding of the subsurface formation and aquifer hydraulics. Traditionally, this groundwater screening option is exercised when the formation is more homogeneous such as a prolific sand and gravel zone or a well-defined higher conductive aquifer. Otherwise, a sample point can be pushed into a zone void of groundwater such as dense clay resulting in a sample void of groundwater.

SimulProbe® Soil and Groundwater Sample Collection

Like the push ahead samplers, the SIMULPROBE is driven ahead of the drilling disturbance. What sets it apart is the ability to collect a soil sample while it collects a groundwater or soil gas sample.

The SIMULPROBE is prepared with a sheath placed around the driven (lower) end of the sampler. The sheath is perforated at the bottom of the borehole when it hits the competent material at the bottom of the drilling operation. Groundwater is then delivered to a vessel in the tool via some small diameter tubes inside the device. It takes more time to set up, but the SIMULPROBE does collect a good (though turbid) groundwater sample. While more expensive than the push ahead samplers, its ability to collect soil and soil gas samples simultaneously can make it a more cost-effective option.

The SIMULPROBE is ideal for sites where soil, soil gas and ground water samples all need to be collected in the same borehole.

These four deep groundwater sampling methods are some of the most common—but there are other options. If you’d like to learn more about groundwater and environmental sampling, click below to watch my on-demand webinar, Sampling 101: Methods of Collecting Environmental Samples.

Drilling Resources & Locations

- National Offices Locations

- Environmental Drilling & Sampling Services

- Drilling Services and Technologies

- Rotary Core Drilling

ABOUT THE AUTHOR

Greg Zekoff

Environmental and Geotechnical Drilling Expert, Retired

Greg Zekoff is a retired registered professional engineer. He served the environmental and geotechnical drilling industry for 35 years. While at Cascade Environmental, Greg worked closely with environmental consultants and engineers solving some of the toughest challenges related to infrastructure drilling, sampling, well installation, and well maintenance. He understands the ins and outs of the major drilling technologies, including auger, sonic, DPT, air and mud rotary. His work with sampling and well construction covers most techniques and drilling methods.

Categories

- Site Remediation

- Drilling

- Careers

- Cascade Chemistries

- Safety

- Site Characterization

- Thermal

- Rotary

- Sustainability

- In Situ Stabilizaton

- High Resolution Site Characterization

- Injection

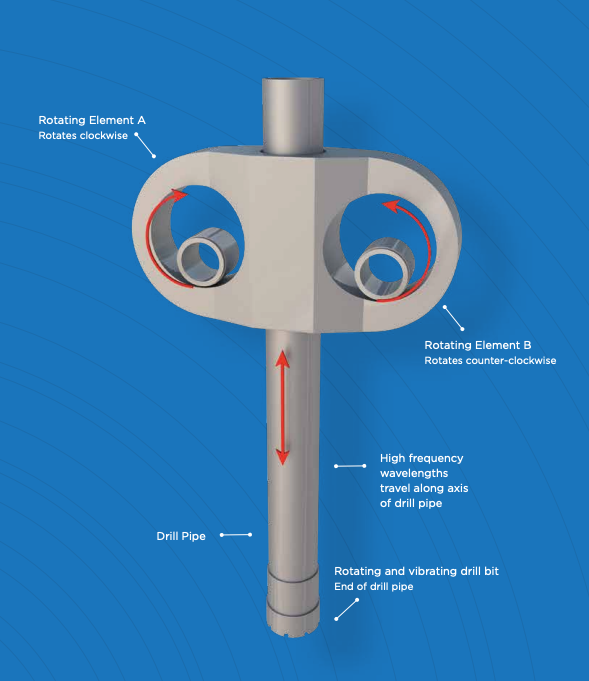

- Sonic Drilling

- Automated injection

- corporate sustainability

- case studies

- in situ thermal remediation

- Cascade Drilling

- Over Water Drilling

- In Situ Stabilization (ISS)

- ISS

- Environmental Remediation