Cost-Effective Groundwater Remediation with Cascade’s ColloidalChem™ Solutions

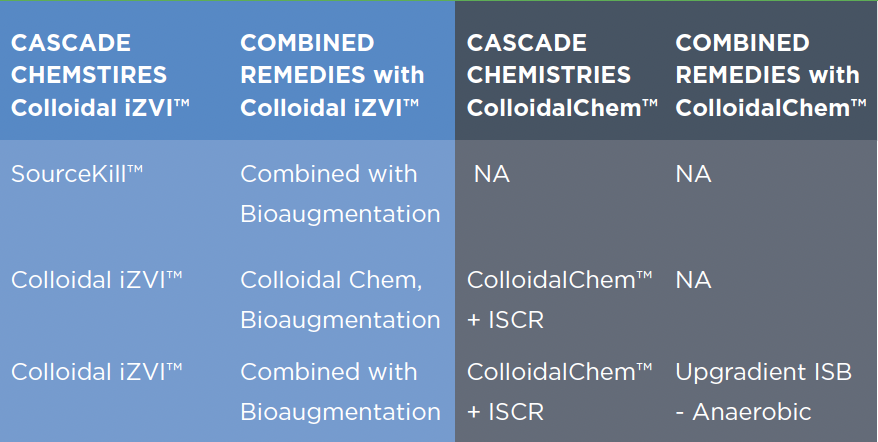

By: Eliot CooperTraditional approaches such as In Situ Chemical Oxidation (ISCO), In Situ Chemical Reduction (ISCR), and In Situ Bioremediation (ISB) rarely meet MCLs for solvents and petroleum, but Cascade’s ColloidalChem solutions achieve remediation targets at a lower cost. Compared to traditional treatment technologies for PFAS, ColloidalChem is the only injectable in situ solution available, thus avoiding the lengthy treatment times, high capital expenditures, tedious long-term operation and maintenance (O&M), and intensive energy requirements of pump-and-treat approaches.

In this blog, you’ll learn more about our ColloidalChem suite of chemistries, the contaminants of concern (COCs) they target, and our groundwater remediation turnkey solutions that are more cost-effective and efficient than traditional approaches.

What is ColloidalChem?

Cascade’s full suite of injectable ColloidalChem groundwater remediation turnkey solutions was developed based on 20+ years of experience and a desire to improve in situ remediation performance utilizing more persistent chemistries. ColloidalChem solutions remediate a wide range of difficult-to-treat contaminants such as per- and poly-fluoroalkyl substances (PFAS), chlorinated volatile organic compounds (CVOCs), benzene/toluene/ethylbenzene/xylenes (BTEX), petroleum, and metals.

Cascade’s ColloidalChem formulations are based on a specialized form of activated carbon engineered to have a particle size of 1-2 microns and a high surface area, providing excellent contact for adsorbing contaminants. These ultra-fine particles are suspended in a liquid medium, enabling low pressure, controlled injection of ColloidalChem to optimize contact with COCs and enable adsorption (Figure 1)

- ColloidalChem™: Comprised of colloidal activated carbon microparticles, which can be injected into groundwater to sequester and treat solvents and petroleum, or to adsorb PFAS.

- ColloidalChem + Bio™: Degrades petroleum with the addition of sulfates that promote the anaerobic decomposition of petroleum compounds adsorbed by the activated carbon.

- ColloidalChem + ISCR™: Remediates solvents, hexavalent chromium, and PFAS mixtures with the addition of base-activated sodium dithionate (patent pending).

- ColloidalChem + Anchor™: Includes an enzyme that reduces the mobility of ColloidalChem over time to maintain a stable permeable reactive barrier (PRB) and control adsorbent mobility in higher groundwater velocity applications (US Patents #11,077,476 and #11,998,964 are licensed by Cascade).

Optimized Injection of ColloidalChem for In Situ Groundwater Remediation

ColloidalChem is injected into target intervals which have been determined to contain the majority of the contaminant mass and flux (plus groundwater velocity), typically in transmissive zones with higher permeabilities.

We perform in situ high resolution site characterization to identify contaminant flux with our Waterloo Aquifer Profiling System (APS)™ technology. This method is a complete direct push subsurface data collection platform, combining high-quality discrete sampling with real-time hydrostratigraphic logging. Over the past 25 years, WaterlooAPS has been utilized in a wide range of environments and can achieve depths of 600ft below ground surface with hybrid drilling methods.

To deploy ColloidalChem we utilize our precision automated injection technology, Pathfinder™, with flow control that adjusts automatically to meet pressure and flow setpoints and avoid exceeding the fracture pressure or the site’s hydraulic capacity. Pathfinder has a manifold system capable of injecting in up to ten simultaneous locations through direct push or injection wells (Figure 2).

Once injected, ColloidalChem is a highly persistent chemistry that can be relied upon for performance over many years, including addressing COCs that have been adsorbed into soil or bedrock.

Benefits of ColloidalChem

Cascade’s suite of ColloidalChem chemistries offers many benefits, including:

- Versatility. ColloidalChem is a versatile remediation solution that can address multiple COCs.

- Ideal for PRBs; Avoids fracking. ColloidalChem is ideal for targeting flux in PRB applications. It can be effectively injected in the subsurface at low pressures without the need for fracturing, which is problematic for achieving contact in transmissive/flux zones.

- Lower cost. Lifecycle remediation costs are lower than traditional technologies due to the shorter time frame required to achieve groundwater MCLs for target COCs. Compared to pump-and-treat approaches, our in situ technique has significantly lower CapEx, O&M, and energy requirements.

- Safety. Our ColloidalChem chemistries have minimal safety risks compared to ISCO, where powerful oxidizers such as permanganate, persulfate, and catalyzed hydrogen peroxide are used. These materials are caustic, corrosive, and highly reactive, often generating significant heat and off-gassing when they react with target contaminants. It is not recommended to inject oxidizers at active petroleum facilities, such as gas stations. Additionally, workers must wear robust personal protective equipment (PPE) to avoid skin, eye, and inhalation contact with these oxidizers. During hot weather conditions, operations undertaken with this PPE are limited to avoid worker heat stress.

- Environmental Sustainability. Compared to pump-and-treat systems, the energy requirements and carbon dioxide emissions produced during ColloidalChem remediation treatment are orders of magnitude less. Additionally, traditional remediation technologies can generate byproducts that may also exceed groundwater MCLs.

In summary, ColloidalChem chemistries enable faster contaminant mass reduction and attainment of MCLs on a wide range of COCs, compared to traditional chemistries that primarily offer mass reduction to support monitored natural attenuation (MNA). Relative to pump-and-treat applications for PFAS, our in situ PFAS sequestration is a more cost-effective and sustainable approach with reduced energy requirements.

Our wrap-around enabling technologies include high resolution site design optimization (HRDO) to define contaminant mass flux using WaterlooAPS, and Pathfinder precision automated injection for optimal COC contact. We also support our highly transparent designs with bench scale and column testing as needed.

We are continuously improving our ColloidalChem formulations, and testing combined spatial and temporal remedies with oxidants, reductants, and bio amendments, along with our own in situ TerraTherm™ thermal technologies.

Our ColloidalChem suite has gained the acceptance of regulatory agencies, consultants, and responsible parties across the U.S. We are always seeking to forge new strategic relationships with consultants interested in specialization with in situ remedies.

Are you ready to enhance your groundwater remediation strategy with Cascade’s advanced ColloidalChem solutions? Reach out today and talk to an expert to discuss your site-specific needs, explore our innovative technologies, and discover how we can help you meet your remediation goals more sustainably and cost-effectively.