Injection Chemistry Transparency for In Situ Remediation Projects: What You Need to Know

While every in situ remediation project is different, all environmental consultants need transparent remediation amendment information for their site. When this detail is clearly explained in a proposal, you’re more likely to experience success in your field application. Below are three considerations to help you mitigate any uncertainty and better understand the details before starting your project.

Will Chemistries Be Measured On Site?

The most important requirement is to ensure the correct quantity of chemistries was delivered to the site. This is easy to do with solids, drums and totes, but bulk can be more challenging. The chemistries most likely will be diluted with water, so the dilution calculation must be precise and water volumes should be measured with an accurate flow meter.

The amount of the chemistry solution injected needs to be measured by a calibrated flow meter specific to the chemistry and expected flow rates. This calibration should be performed and documented on site before the commencement of injection.

You should also consider the total volume injected into the well screen or direct push interval. With direct push, it’s vital to have a second line of evidence that the actual depth of the injection tool is at the correct interval. This can be done by having the total amount of rods and injection tools necessary for the injection location set aside at the location that can be counted, whether it’s a bottom-up or top-down injection. It’s crucial to ensure all direct push locations are surveyed, especially if they are going to be offset during future injection events.

In addition to the above, a chemistry inventory reconciliation methodology should be implemented as a second line of evidence to ensure that throughout the duration of the injection, the remaining chemistries are in balance with what has already been injected. Getting to the completion of the injection with not enough chemistry remaining or too much remaining raises both financial and conformance to design issues. This becomes more of a problem with bulk delivery of liquid chemistries in tankers since other containers can be counted and volumes measured visually, but it needs to be done consistently and documented with daily injection logs.

How Will the Chemistries Be Injected?

It’s critical to understand the equipment used for injection, including mixing, pumps, recirculation systems, injection hoses, injection tool diameters and screen lengths. You also need to be aware of the applicability of continuous monitoring equipment. Force fitting available injection systems lead to field challenges during implementation. Ensuring your field services subcontractor discloses this information in a proposal helps prevent any unforeseen complications Complete transparency on all the above equipment needs to be disclosed in a proposal to do the work or at least prior to site mobilization.

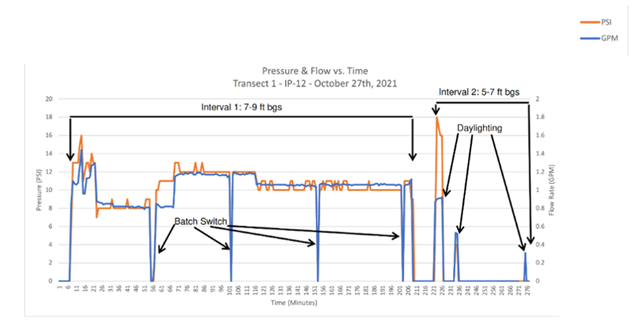

In addition to the amounts of chemistries injected, understanding how they are injected is even more critical. Injection parameters like pressures and flow rates from initial startup to steady state injection conditions need to be documented. It is well-known that too much injection pressure can fracture the formation and lead to short circuiting and possible daylighting. Too much flow can lead to groundwater mounding above the target injection interval. Both situations mean the expensive chemistries you’re injecting are not contacting the contaminants you are treating.

How Will Amendment Volumes Be Documented?

Even though continuous analog pressure gauges and turbine flow meters may be sized correctly for the injection parameters, there’s still risk of inaccurate data logging. This risk increases when injection operators estimate averages or quick changes in injection pressures and flows are missed. This can result in inadvertently fracturing the formation with the same contact issues discussed above. Coupling this inefficiency with injection at multiple simultaneous locations, especially when the injection operator is involved in other tasks, further impacts the ability to record key injection parameters manually.

Our industry is shifting toward the continuous digital recording of these parameters from the start to completion of an injection location. Continuous digital recording provides a robust line of evidence and documentation on the actual adherence to injection design parameters. This becomes even more important when evaluating post-remediation groundwater data and planning for future events. Trying to troubleshoot from manual data is nearly impossible. Consider how many injection reports you’ve seen that provide no help in optimizing future remediation events.

An example of a digital continuously recorded injection log is shown in the figure below.

Data Transparency Leads to Success

When considering the number of dollars invested in site characterization, regulatory reporting, workplans, public participation, chemistries, dilution water applied and overall safety practices, it’s imperative that total transparency is practiced during the injection event. Anything less can put your project success at risk and lead to costly mistakes or unexpected delays.

Learn more from this webinar The Importance of Data Transparency for Remediation

About the Author

Eliot Cooper is the Vice President of Technology and Business Development. In this role, he helps clients design efficient and cost-effective remedies using high resolution site characterization (HRSC) and a vast array of remediation options. His specialty is finding the right combination of tools and technologies for complex sites and ensuring every step of the remediation process is optimized to achieve results.

Eliot Cooper is the Vice President of Technology and Business Development. In this role, he helps clients design efficient and cost-effective remedies using high resolution site characterization (HRSC) and a vast array of remediation options. His specialty is finding the right combination of tools and technologies for complex sites and ensuring every step of the remediation process is optimized to achieve results.

Eliot draws on a career that spans more than 30 years in the environmental remediation industry and includes hundreds of projects nationwide. He’s remediated sites that involved hex chrome, fuel spills, and chlorinated solvents. He specializes in injected remedy delivery, remediation design support, characterization of VOCs, and tackling complex sites by combining multiple remediation technologies.

Eliot previously served at the Environmental Protection Agency in both air pollution and hazardous waste management programs, as well as in the private sector providing thermal combustion and in situ remediation field services. Eliot now leads Cascade's in situ remediation solutions team to evaluate available technologies or Cascade Chemistries to meet client goals, provide advanced delivery techniques, and ensure HRSC results in actionable solutions.