Safe and Preferred Methods for Drilling Earthen Dams and Levees

By: Jim McCombsAs critical infrastructure such as dams and levees age over time, there will inevitably arise a need for drilling, either for exploration purposes or foundation repairs. Before any drilling program starts, it is important to understand the potential risks of damaging these sensitive structures if the wrong drilling methods or techniques are utilized. Depending on the nature and characteristics of the earthen structure, there may be a few options to choose from.

Over the past couple of decades, Cascade has had the opportunity to provide critical drilling services on several high-hazard dams and levees throughout the nation. Through these projects, many of our drillers have gained the necessary experience required to drill these structures safely. In this blog post, we would like to share what we have learned as well as provide some insight into a few of the industry standards and regulation-driven practices.

Why Do We Need to Drill into Earthen Embankments Such as Dams and Levees?

The three main reasons drilling needs to be conducted on earthen embankments are: exploration drilling, instrumentation installation for monitoring, and foundation remediation for seepage control. However, before we begin any drilling program, we need to ask the question: “Is the drilling need greater than the drilling risk?” Additionally, it is important to understand that not drilling and ignoring a situation also carries a risk.

Let’s expand our discussion on the three key reasons for drilling earthen embankments.

Exploration drilling’s main purpose is to safely retrieve samples or cores of the internal structure to visually inspect the condition of soils and other materials used during the dam’s construction. These exploration boreholes can also alert us to any internal weathering, high potentiometric surfaces, piping of materials, erosion, and the nature of the important contact between the foundation and embankment structure of the dam.

Drilling for installation of monitoring equipment instrumentation is also common practice and a necessary part of identifying any existing or future issues in an earthen embankment. The instrumentation installed in these structures are designed to measure very small shifts, movements and internal changes in hydrostatic pressures. To install these devices at the proper depths, drilling a borehole is part of the process.

Lastly, once an earthen embankment has been determined to be in critical need of foundation repairs, drilling becomes a larger part of the process. Boreholes are drilled to reach the desired zones of the embankment or foundation where grouting procedures are required to mitigate seepage control. In some cases, multiple drilling technologies are utilized based on material types encountered, depths, and engineering regulations and restrictions placed by the embankment owner or regulating organization.

What Are the Risks?

The primary risk when drilling into earthen dams and levees—and the one that demands the most attention—is hydraulic fracturing of the embankment. This occurs when borehole pressures exceed the minimum confining stress, causing fractures to propagate through the structure.

Hydraulic fracturing, sometimes called hydrofracturing, can be triggered by excessive pressures from water, mud, or air during drilling. When these pressures exceed those of the surrounding materials, fractures can form and spread, increasing pore pressures and creating new zones of weakness. This can compromise the integrity of the embankment, potentially leading to structural failure.

Given that earthen dams and levees are often already sensitive structures, any drilling activity must be carefully managed to avoid unintentionally worsening the situation.

How Do We Minimize the Risks?

A key and often-cited document published by the United States Army Corps of Engineers (USACE) provides critical guidance: “USACE ER 1110-1-1807 Drilling and Invasive Activities at Dams and Levees.” It’s important to note that if you are working on a structure owned by the USACE, this is an Engineering Requirement and must be adhered to unless a written variance has been provided. In this document, you will find all the “do’s and don’ts” of drilling in earthen embankments. Lastly, there are also minimum experience requirements established for the driller and other field personal.

Additionally, other federal oversight organizations, such as the Federal Energy Regulatory Commission (FERC), adopt much of this guidance as well.

So, what are some of the risk minimization guidelines outlined in this document?

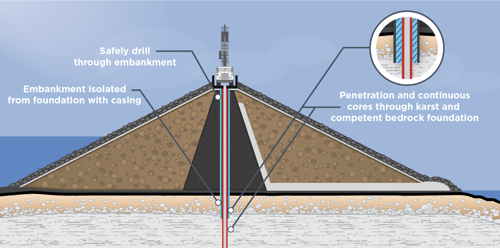

The main guidance in this document states that during drilling and similar invasive activities, embankment pore pressures cannot be increased. This means that you cannot “pressurize” drill with circulating drilling systems such as mud, water, or air that are in contact with the embankment. Moreover, air-drilling is not acceptable even in bedrock. Boreholes in unconsolidated materials must be supported with casing to prevent collapse, mitigate piping, and, whenever possible, advanced in these zones using “dry-drilling” techniques. These are techniques that drill without the use of any fluids.

What Are the Preferred Drilling Technologies?

As part of your Drilling Program Plan (DPP), you will need to decide on the best method to execute your work plan. Above, we discussed some of the inherent risks of drilling in earthen embankments, as well as established guidance for mitigating these risks.

One of the most widely accepted drilling technologies that checks all the boxes is Sonic Drilling. This technology is able to drill into earthen embankments very efficiently, provide high-quality samples, and advance a core and casing tooling system using dry drilling techniques without increasing formation pore pressures.

Sonic drilling is also capable of maintaining borehole deviations of less than 1–2% verticality, which is critical for drilling close to important dam features or designing closely spaced grout curtains. This is why sonic drilling is commonly the optimum choice for drilling earthen embankments. However, in some unique cases, other technologies may also be used depending on the application.

As discussed, drilling earthen embankments such as dams and levees can present risks to their structure that must be considered before drilling begins. The plan to drill should not impact or harm the integrity of an already at-risk structure by introducing circulating fluids or compressed air during drilling. Therefore, choosing the correct drilling method and experienced individuals for advancing these types of borings is crucial in mitigating the risks.

ABOUT THE AUTHOR

Jim McCombs

Key Accounts Manager

Jim is a geologist and the Key Accounts Manager at Cascade. He has spent most of his career helping clients troubleshoot difficult environmental and geotechnical projects using sonic drilling technology. Jim is the go-to guy for drilling projects with difficult formations, solid buried waste, low thresholds for borehole deviation, and other challenging components. On the toughest sites, he often develops a rig platform and tooling modifications to overcome obstacles.