Why Data Management is One of the Most Important Parts of a Thermal Remediation Project

By: Cascade EnvironmentalThermal remediation remedies can be highly effective but also resource intensive. Thermal project sites are also dynamic, with constantly changing variables that impact the final outcome of the project. Real-time process numbers and field data allow us to monitor those changes and use the information for continued optimization of the treatment approach—but data management is often the most underrated aspect of a thermal remediation project. Not understanding the importance of proper data gathering and interpretation during a thermal project can be costly and affect project success.

In this blog post, I’ll explain how data management impacts a thermal remediation project, but if you’re interested in learning more, join me for my webinar later this month, titled “Data Management: The Most Underrated Aspect of Thermal Remediation Operations.”

Because a thermal system is a constantly changing entity with many characteristics, collected field data is essential in informing project members of the need for operational changes that can optimize the heat-up process. Proper data collection and analysis also provides continuous feedback as to whether volatilized mass is being captured, the project is on track, and the treatment goals are being met.

Data related to the operations of the above-grade treatment system is also monitored and ensures that the extracted chemicals are properly treated prior to discharge of extracted vapors and liquids. This, in turn, helps to minimize the wear and tear on project equipment and monitor our compliance with applicable process permits.

TerraTherm, a Cascade Company shares pertinent project data real time on a project-specific webpage. Clients may also request site-specific items to be included in weekly, bi-weekly or monthly reports, that highlight specific areas that they are concerned about. Since not all data can be uploaded in real time, these reports allow for a greater grasp of operations and give the client access to pertinent information.

This type of actionable information provided by data management streamlines the path to successful completion of a project.

MAINTAINING THE HIGHEST MASS REMOVAL WITH THE LEAST AMOUNT OF ENERGY

Depending on the complexity of a site and the specific remedial objectives, any number of data analyses can be performed, but the quantity and quality of data are paramount. The data is used to create detailed mass and energy balances that ultimately enable an analysis of what is often the client’s greatest concern: the energy input versus the contaminant mass output. At first glance, analysis of input vs. output seems straightforward, but a wellfield has many variables and is continuously changing. When monitored properly, these variables can be predicted, manipulated and optimized to accomplish the treatment goals.

To maintain the highest mass removal while consuming the least amount of energy, key operational characteristics are investigated. A few major characteristics include:

- Subsurface temperatures and mass removal rate – by monitoring the subsurface temperature, we can predict when the peak mass removal will happen and when the mass removal rates will taper off when entering the thermal polishing period.

- Vapor extraction vacuum, flows and temperatures – instruments installed in vital locations allow the operators and engineers to maintain pneumatic and hydraulic control and capture of the vapors including steam generated during the subsurface heating.

- Energy – monitoring the energy injected into the subsurface and keeping track of the energy coming out in the different phases allow the operators and engineers to optimize the heat in the subsurface and focus on lagging subareas of the wellfield.

REAL-TIME MONITORING

Real-time monitoring of data is crucial for project success. TerraTherm and our European partner, Krüger, have developed an insight portal, which delivers real-time information on a variety of key variables, allowing us to keep current with collected data. The layout of the website is project-specific and has the capability to be set up with different menus, display images, graphs and tables. Project files can be uploaded to the portal as well. The portal also contains our data plotter, a customized user interface software allowing for real-time connection to the project process and temperature database. The website is accessible to our project team and our clients, strengthening the lines of communication and data sharing.

EXAMPLES FROM THE FIELD

Data management allows us to be confident in our conclusions as all decisions are based on a plethora of variables that have been collected and analyzed over many projects.

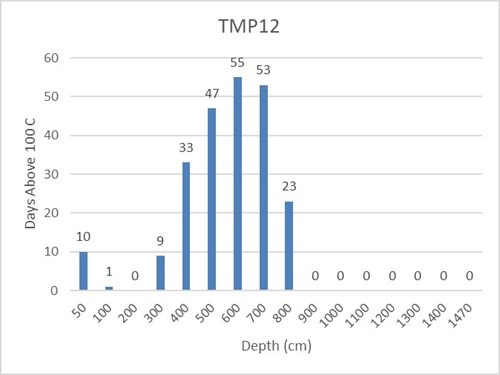

An example of how we used the data management system at one of our international projects can be seen in the figure below. The figure shows how many days each sensor at a specific temperature monitoring point (TMP) had been above the temperature goal. The site extended down to 1470 cm; however, temperature increases didn’t occur at the deeper depths. The data was analyzed closely and compared to other wellfield data and it was discovered that a vapor extraction well (VEW) close to the TMP in question also had low-temperature readings. By combining the data, it was determined that there was a higher than expected influx of cooling groundwater at a specific depth. The liquid extraction strategy was optimized in this area to stymie the influx of cold water. Soon after, a temperature increase was seen in the depths that were originally lagging. This is a prime example of how combining data can lead to optimization of the thermal system.

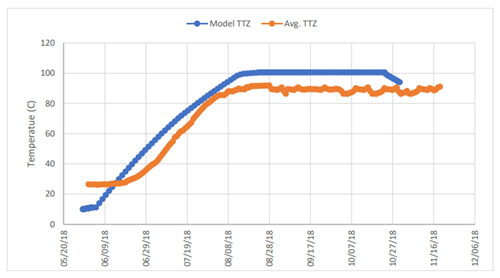

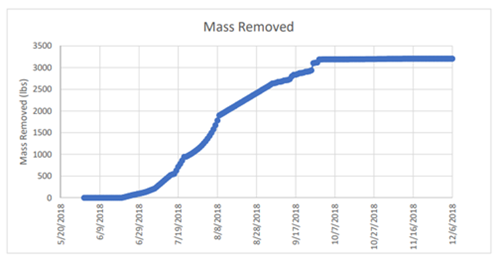

Another example is shown below. The average temperature of the target treatment zone (TTZ) did not reach what the model temperature had predicted, due to excessive cooling in the upper portion of the site. However, after looking at the mass removal curve generated from the process data, including energy input, vapor exchange and in situ steam generation, as well as looking at historic data from sites with similar contaminants, it was determined that the combined thermal treatment theoretically had been achieved, despite of the lag in temperature achievement. To confirm the theory, hot soil sampling was initiated, which came back with favorable results allowing the site to be shut down. Data management allows us to predict and assess the situation and determine operational success, even when it seems that initial design goals are not being achieved.