PFAS Regulatory Roundup

PFAS Remediation Technologies

Effective PFAS remediation requires a holistic approach. A remedial strategy for plumes may not be optimal for the source zone.

Thermal Conductive Heating for the Source Zone

Thermal conductive heating (TCH) is a promising technology for the remediation of highly concentrated PFAS-contaminated source zones. TCH can be applied either in situ or ex situ in specially constructed piles and involves the insertion of heaters into the contaminated media (soil, sludge, sediment, soil washing fines, etc.), and the application of heat to the subsurface to reach the temperatures that can volatilize and thermally degrade the PFAS, typically 350 to 400C.

Source zone treatment via TCH has advantages over other PFAS remediation technologies. One being that TCH can treat the complete range of target as well as non-target PFAS compounds, today's and tomorrow’s regulated contaminants. TerraTherm’s approach for TCH also incorporates innovative high-temperature thermal treatment of extracted vapors to essentially eliminate discharge of PFAS compounds to the atmosphere and meet stringent air emission standards. Importantly, the complete destruction of PFAS compounds provided by TCH, eliminates long-term liabilities of other treatment approaches based on in situ stabilization or excavation and landfill disposal.

Check out recent thermal treatment of PFAS research or view webinar on treatment strategies for high concentration of PFAS in source zones.

Plume Treatment with ColloidalChem™ and ColloidalChem +Anchor™:

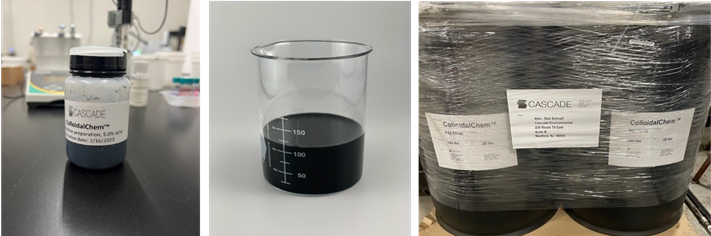

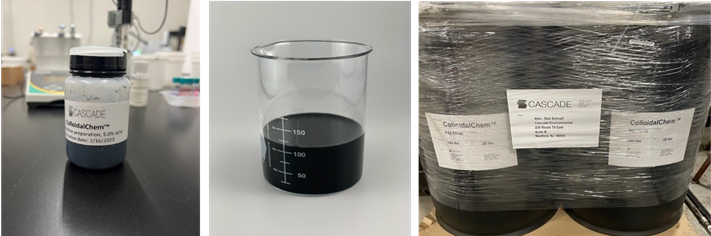

Even with successful source zone treatment of soil, PFAS groundwater concentrations remain a concern. How can you cost-effectively address the groundwater plume? ColloidalChem is a group of high mobility and low pressure, injectable colloidal activated carbon products designed to target difficult-to-treat contaminants like PFAS. ColloidalChem +Anchor is a patented injectable colloidal activated carbon with an integrated enzyme technology to control mobility in permeable reactive barrier applications.

These amendments are easily injected with our Pathfinder™ technology, the industry’s first fully automated injection system, into transmissive zones contributing to PFAS Flux.

Data collected in our R&D lab indicates that ColloidalChem can meet EPA’s proposed MCLs. Additionally, Cascade can anchor the high mobility ColloidalChem within the PRB with ColloidalChem +Anchor technology. This anchoring technology is critical to the efficacy of PRBs for higher seepage velocities, which is typically the case in transmissive flux zones.

Pictured left to right: ColloidalChem™ for Department of Defense testing a sample of the injectable colloidal activated carbon product ColloidalChem, 55-gallon drums of ColloidalChem ready for injection.

Watch the webinar to learn about contaminant flux characterization and design optimization testing for PFAS plume treatment.

Watch PFAS 102 >>