The GeoSierra Trenchless PRBs, a Cascade method, transform the installation of Permeable Reactive Barriers (PRBs), delivering cost-effective and sustainable groundwater remediation. This trenchless technology enables the construction of PRBs at depths exceeding 150 feet, far beyond the capabilities of conventional methods. Using the GeoSierra Trenchless GeoSierra approach, Cascade has successfully installed PRBs across diverse geological conditions, from silts and clays to glacial tills and permeable sands.

Why Choose the GeoSierra Trenchless PRBs for PRB Installation?

The GeoSierra Trenchless PRBs technology offers unmatched benefits for deep-reaching, cost-effective, and sustainable groundwater treatment.

Long-Term Cost Savings

Passive treatment significantly reduces ongoing operational expenses, making your overall remediation strategy more economical over time.

Minimal Site Disturbance

Because the method is trenchless, there’s no large-scale excavation and minimal disposal of contaminated material. This helps maintain regular site operations and reduce community impact.

Deep Reach

Install Permeable Reactive Barriers at depths of 150 feet or more, surpassing the capabilities of conventional methods and allowing you to address complex contamination plumes.

Sustainable Remediation

Passive PRBs preserve natural groundwater flow and require no continuous energy input, aligning with green remediation goals and reducing carbon footprint.

Proven Longevity

Over 30 years of reliable performance in real-world applications demonstrate the method’s effectiveness and durability.

What is a Permeable Reactive Barrier (PRB)?

A Permeable Reactive Barrier (PRB) is a passive, in situ solution for treating contaminated groundwater. Designed to intercept and remediate contaminant plumes, PRBs use reactive materials to degrade or immobilize pollutants as water flows through them.

How PRBs Work

PRBs are placed in the path of a contaminant plume, allowing groundwater to flow through reactive media that chemically or biologically treats the pollution.

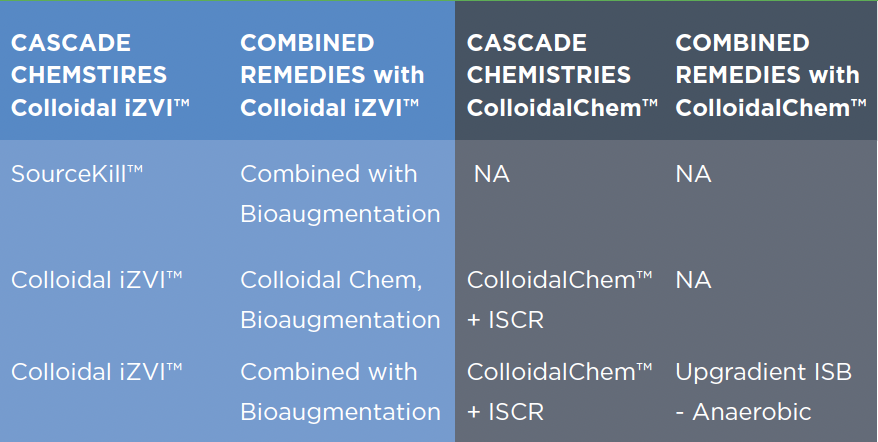

Common Reactive Materials

One example is Zero Valent Iron (ZVI), widely used for treating chlorinated compounds and heavy metals. ZVI effectively degrades contaminants like trichloroethylene (TCE) or immobilizes metals such as chromium.

Key Advantages of PRBs

- Sustainable Solutions: Requires no external energy source, making it an eco-friendly remediation option.

- Regulatory Approval: Widely recognized and endorsed by environmental agencies for groundwater cleanup.

- Wide Applicability: Applicable to volatile organic compounds (VOCs), heavy metals, and more.

- Proven Performance: Over 200 PRBs have been installed globally since 1991.

How the VIP Method Works

Using a proprietary, food-grade gel, the GeoSierra Trenchless PRBs method injects solid amendments such as iron filings into the subsurface through specialized mechanical casings. This trenchless process ensures a continuous, permeable barrier without disrupting groundwater flow.

The Role of Pore Pressure Relief (PPR)

PPR technology controls the direction of injections to create a coalescent PRB. By relieving excess pore pressure, the formation’s permeability is preserved, and the barrier remains consistent throughout the target zone.

Food-Grade Gel & Specialized Casings

The gel acts as a carrier fluid for the solid amendment, ensuring uniform distribution. Mechanical casings then guide and monitor these injections, allowing for real-time adjustments.

Ensuring Continuous Barrier Formation

Real-time monitoring confirms that injections overlap properly, forming a seamless barrier. This approach avoids gaps or voids that might allow contaminants to bypass the PRB.

Trenchless PRBs Advantages:

- Precise Installation: Adjustments are made on the fly for optimal placement.

- Versatile Applications: Suitable for both deep or shallow site conditions, including urban or sensitive environments.

- Eco-Friendly: Eliminates heavy excavation and large-scale soil disposal.

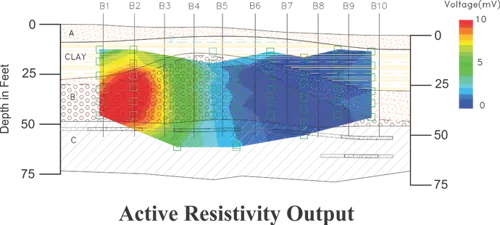

Real-Time Monitoring & Quality Assurance

Cascade employs several quality assurance techniques to verify barrier placement during installation, including advanced resistivity monitoring. This innovative technique maps the geometry of the barrier in real-time, ensuring:

- Full barrier continuity with no gaps or voids.

- Consistent amendment loading and permeability.

- Minimal impact on the surrounding geology and groundwater flow.

Designed for Success

Our expertise goes beyond installation, offering collaborative design and planning services tailored to each site’s unique challenges.

- Site-Specific Testing: Laboratory analyses to optimize barrier performance.

- Hydraulic Testing: Advanced techniques to confirm groundwater flow compatibility.

- Custom Equipment: Specialized tools for seamless design and construction.

Applications and Advancements

The GeoSierra Trenchless PRB method isn’t limited to PRBs. Cascade also uses the method to create Permeable Reactive Treatment Zones (PRTZs) for injection-based remediation and to enhance well permeability in challenging geological settings.

Permeable Reactive Treatment Zones (PRTZs)

PRTZs operate similarly to PRBs but can be installed strategically for plume management or hotspot treatment, adapting to various contaminant profiles.

Enhancing Well Permeability in Challenging Conditions

The technology can also improve the efficacy of existing wells, especially in tight or clay-rich formations, by increasing flow pathways without heavy drilling.

Single- and Multi-Azimuth Installations

We tailor the barrier orientation—whether single or multi-azimuth—to suit confined spaces, urban environments, or sites with multiple contaminant sources.

Ready to Solve Your Groundwater Challenges?

At Cascade, we’re committed to delivering innovative, proven solutions for groundwater remediation. Whether you’re facing complex geology, confined spaces, or deep contamination, our GeoSierra Trenchless PRBs method can help.

Contact Us Today to learn how we can partner on your next project.